Electronics Manufacturing

In the intricate world of electronics manufacturing, where microscopic components orchestrate the marvels of modern technology, the presence of even the smallest extraneous particle can have catastrophic consequences. Enter particle counters, the unsung heroes of this industry, vigilantly guarding against contamination and ensuring the flawless production of the electronics that power our lives.

The importance of particle counters lies in their ability to monitor and control the number and size of particles present in the manufacturing environment, including cleanrooms, assembly lines, and packaging areas. Contamination by particles, such as dust, fibers, and metallic shavings, can disrupt sensitive circuits, lead to component failure, and ultimately result in product malfunction.

Imagine a single dust particle landing on a delicate microchip during assembly. This seemingly insignificant speck could disrupt the flow of electricity, causing the chip to malfunction and rendering the entire device useless. Particle counters, acting as vigilant sentinels, measure and detect such contaminants before they can cause irreversible damage. But the role of particle counters extends beyond mere detection. By providing real-time data on airborne particle levels, they enable manufacturers to implement targeted solutions to address contamination sources. This could involve improving air filtration systems, implementing stricter cleanroom protocols, or modifying manufacturing processes to minimize particle generation.

Enhanced product quality

By helping to prevent contamination, particle counters ensure the reliability and performance of electronic devices. This translates to a higher yield of functional products, reduced production costs due to fewer rejects, and increased customer satisfaction.

Compliance with regulations

Various industries, such as medical device manufacturing and aerospace, adhere to stringent regulations regarding particle contamination. Particle counters provide the data needed to ensure compliance with these regulations, mitigating risks and ensuring product safety.

Real-time data from particle counters allows manufacturers to identify and address contamination issues promptly. This proactive approach facilitates continuous improvement of manufacturing processes, optimizing efficiency, and minimizing waste.

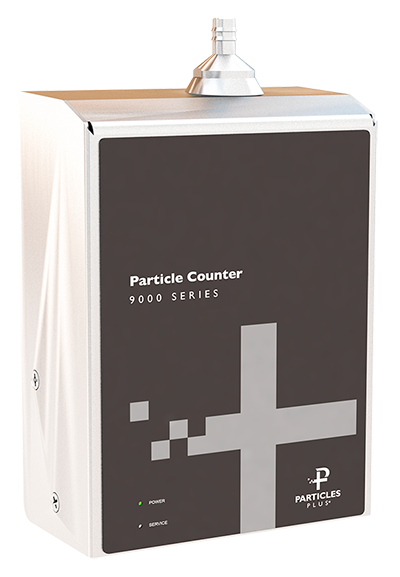

Particles Plus Instruments for Electronics Manufacturing

Remote Air Quality Monitors

Particles Plus® instruments allow for remote operation and diagnostics over an IP connection from anywhere in the world. The remote diagnostics allows the Particles Plus® authorized technical staff to access the instrument and diagnose issues quickly, often without having to send the instrument in for service. This feature also allows for field-upgrades of the instrument software so updates and new capabilities can be added as they become available.