OEM SOLUTIONS

Particles Plus® OEM sensor and vacuum pump technology provides distinctive, matchless performance in extremely compact designs for a wide range of indoor or outdoor air monitoring applications. The Particles Plus® cloud based monitoring system takes advantage of the versatile communications capabilities and Internet of Things functionality to communicate, record, and provide online access and tools for any site monitoring applications.

Airborne Particle Counter Sensors

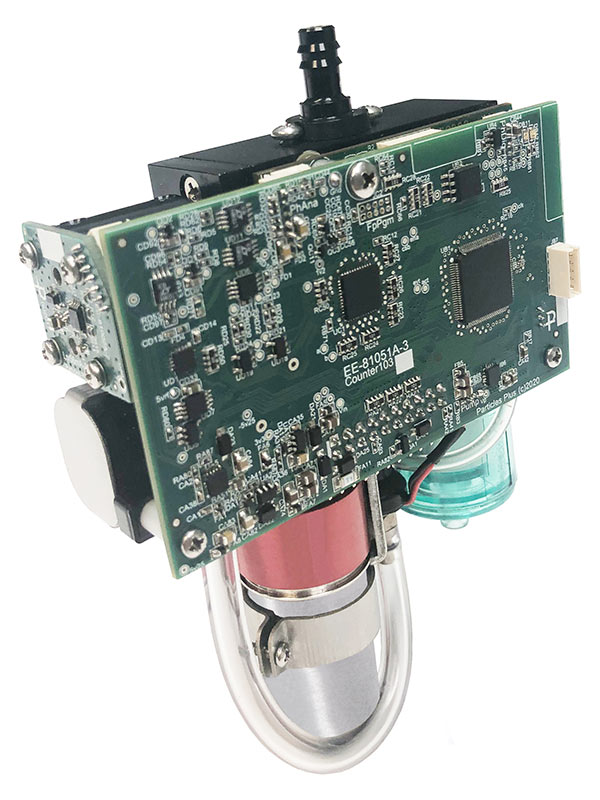

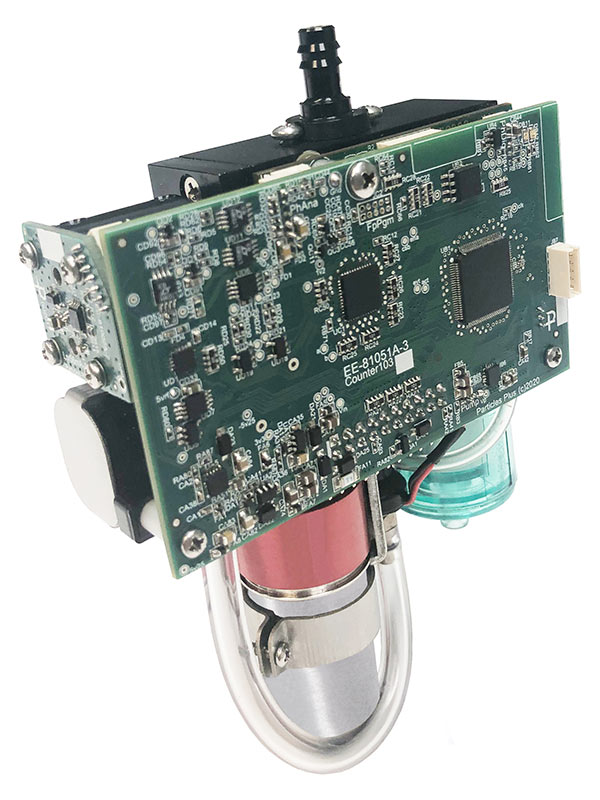

9300P-OEM

0.3 – 25.0 µm @ 1.2LPM

9301P-OEM

0.3 – 25.0 µm @ 2.83LPM

15000-OEM

5 nm – 3.0 µm Water-based

Vacuum Pumps

Rotary Vane Vacuum Pumps

The Particles Plus® Brush and Brushless Rotary Vane Vacuum Pumps produce either vacuum or pressure by compressing or expanding a volume of gas within a cylindrical steel housing.

Within the housing is a compressed graphite rotor with two slots that contain compressed graphite vanes. The rotor is mounted to the shaft of the motor and is positioned off-axis to the center of the steel housing. As the motor shaft rotates, the vanes are pulled outward by centrifugal force.

The vanes then make contact and slide against the inner surface of the steel housing, forming two internal and enclosed volumetric areas, which increase or decrease as the rotor turns, with a vacuum being created on the increasing side and pressure on the decreasing side.

There are two ports positioned at the points of minimum volume with the increasing side being the vacuum port and decreasing side the pressure port.