Why Particles Plus?

Processing Power

Particles Plus® instruments contain multiple high-end controllers, graphics controllers, high-speed programmable logic and intelligent peripherals. This allows the instrument to process and log data at full speed while allowing the user and/or remote users to access the instrument or data without compromising the performance of the instrument.

The instrument can sample airborne particulates for applications with many millions of particles per cubic foot, while also processing and logging temperature, humidity, CO2, TVOC and internal diagnostic sensors. At any time, even during sampling, a local user can scan through collected data on the local display, while a remote user accesses the instrument through a web browser and a remote monitoring system interfaces with the instrument to collect stored data. All of these functions, and more, can occur simultaneously without interruption or degradation of any function.

Patented

Remote Diagnostics & Configuration

Particles Plus® instruments allow for extensive remote diagnostics over an IP connection from anywhere in the world. This feature allows the Particles Plus® authorized technical staff to access the instrument and diagnose issues quickly, often without having to send the instrument in for service. This feature also allows for field-upgrades of the instrument software so updates and new capabilities can be added as they become available.

User questions about the operation of an instrument can be addressed remotely by a qualified technician. The remote diagnostics allows for the technician to access the instrument remotely to review the configuration and hundreds of internal parameters within the instrument. If there’s an issue it often can be diagnosed and addressed remotely.

If the decision is made to have an instrument reconfigured to add features or to change the basic performance level, this can achieved by contacting Particles Plus. A configuration file can be provided that will modify or upgrade the instrument, for example reconfiguring a 3 channel instrument to a 6 channel instrument.

Patented

Annotations

Particles Plus® Annotations are note fields that can be added to any data record at any time during or after sampling, to current or to previously recorded data. Particles Plus Annotations can be used in a wide variety of ways, for example:

- to explain particular aberrations in the data, “door opened during sampling”

- to note the location, “Gowning room”

- to note where a particular sample took place, “Room 1234b, air vent”

- to note external conditions during a sample, “Room H62, air handler active”

- and in many other ways

Annotations minimizes the need for external notes and reduces the chance of errors associated with external notations.

Patented

Power Management Modes

Particles Plus® instruments incorporate industry-leading battery technology that provide the longest runtimes available. In addition to advanced battery technology, the instruments also have sophisticated power management. Instruments can be configured to lower their power profile in various ways when the units are idle. This includes simple things like dimming the screen and putting various subsystems into sleep mode when not in use. Particles Plus® Power Management also includes the option of putting the entire instrument to sleep when idle between samples.

When Sleep Mode is configured, the instrument will go to sleep if the delay/hold times between samples are longer than a user-specified period. While asleep, the instrument will consume very little power and will consume a normal amount of power only when the instrument wakes up to sample. This can be done repeatedly to give very low overall power usage. Sleep Mode would typically be used when powered by the battery, with the unit placed in a long-term monitoring or audit situation. If the instrument slept half the time, the user could effectively double the battery life. If the instrument slept 90% of the time, the user could achieve up to 100 hours of battery life on a single charge.

In addition to high-capacity and power-management modes, Particles Plus® batteries have on-board processing that manages the battery’s safety, fuel gauge and cell balancing. These features improve the capacity and longevity of the battery pack by several years. The stored information remains within the battery. If the battery was to be moved from instrument to instrument, the information is contained within the battery.

Patented

Real-Time Meter

The Real-Time Meter provides a visual and auditory means of displaying count data using a histogram with a log scale that gives a relative indication of particulate traffic for each channel. The “Range” slider adjusts the sensitivity of the counters. The slider can be adjusted as the instrument moves nearer or further from the source of contamination to keep the maximum channel near the middle of the indication range. In this way, the Real-Time Meter provides strong visual and auditory feedback of the particulate data in real-time.

The feature can be used to visualize the particle rates of the data arriving at the instrument in real-time. It’s much simpler to visualize than viewing the numerical differential channel figures. The feature might be used by users to simply visualize the ratio of particles per channel arriving at the instrument in order to easily see the distribution of particles by size.

Using the Range slider makes it a powerful tool for tracking particle events to their source. Adjusting the slider as the counts saturate the channel of interest, increases the local sensitivity of the instrument making it very useful for detecting small variations in particle counts for the channel of interest. This allows for ease in distinguishing small variations in counts and thereby more easily track the particles to their source.

Patented

Sampling & Logging

Particles Plus® instruments can store up to 45,000 data records, each record encompassing comprehensive data for each specific sample. At a rate of 1 sample per minute, the instrument can record a full month’s worth of data before older records are overwritten. If sampling every 15 minutes, more than 15 months of data could be stored.

The user-interface makes scrolling through data fast and intuitive. The charting display helps provide easy visualization of issues or areas of interest within the data directly on the instrument.

Each data record includes data for all the channels, multiple instrument parameters and environmental sensor values, annotations, location and recipe data.

Particles Plus® instruments allow up to 1,000 user defined locations and up to 50 different sampling recipes (i.e. number of samples, sample time, intervals and more). Locations are very useful in situations where the instrument is used to routinely perform the same sampling task. For example, if the instrument is used to validate various locations periodically then these locations and their particular sampling profiles (recipes) can be pre-entered. Then the user can simply select the location to be sampled and the instrument will already be set up for that sample. The data will be tagged automatically with the location and sampling information.

Locations can also be used as a generic term associated with a particular recipe. A particular sampling recipe can be used without having to create a unique location for what might be a one-time sampling event. In such a case, the annotation feature can be used to identify the particulars of that sampling event.

Common Hardware

The Particles Plus® common hardware and firmware architecture for a large family of products provides a lower cost of ownership, and significantly simplifies service and support. As many of the Particles Plus® products utilize the same subsystems it drives down the cost, which allows Particles Plus to offer enhanced capabilities across the entire product line at a competitive price.

Common hardware and firmware also provides an upgrade path allowing an instrument to be reconfigured into a different instrument thereby allowing users to add features or capabilities to an existing instrument in order to extend its life or feature set, rather than having to buy an entirely new instrument.

Patented

User Interface

Dedicated graphic processing, which includes a 32-bit controller, graphics controller and 16-bit color interface improves responsiveness and resolution, and provides for more detailed graphics. The Particles Plus® architecture provides for a richer interface with more detailed data. Navigation is simplified by allowing the user to easily switch between tabular data views, real-time graphing & charting.

The local processing power improves responsiveness allowing the user to scroll quickly through large amounts of archived data without impacting the instrument performance in the collection of new data, or compromising throughput of external interfaces. The entire user interface is always available, even while sampling.

User interface features can be accessed through traditional hierarchical menus or in many cases directly through icons on the main screen. This streamlines navigation, making access of often used features fast and intuitive. For example, touching the battery icon on the main screen brings up the current state of the battery, while also providing other battery details such as battery temperature, state-of-charge, percent of life and more. Features like channel management, environmental sensors, time/date, etc. can all be accessed either through menus or by touching the associated icon on the main screen.

Powerful data representation options like charting and the patented Real-Time Meter provide sophisticated means of viewing data. Some of these are available during sampling and can also be viewed as stored (archived) data.

Below is a summary of some of the user-interface features:

- Entire interface is accessible while the unit is sampling

- Many features accessible both hierarchically and through icons on the main screen

- Data can be represented in several ways: tabular differential/cumulative, Real-Time Meter, graphs and more

- Both new data and archived data can be represented in many of the views above

- Differential and cumulative data can be displayed simultaneously on the main screen, zoom screen and stored (archived) data

- A zoom mode allows tabular data to fill the screen increasing legibility at a distance

- Data can be displayed with various units: particulate counts, cubic-feet, cubic-meters, Liters, Mass-concentration (μg/m3)

- Unique environmental display screen provides large, selectable size Particulate Matter (PM) indication for mass concentration measurements

Intelligent Peripherals

Each subsystem in a Particles Plus® instrument has its own local processing. The photo-amplifier, pump controller, temperature/humidity sensor, battery pack, and other key functions operate independently and in parallel within the system. The various subsystems process data locally and pass data back to the main controllers for display or logging, providing a significant increase in performance for the system and allowing enhanced diagnostics and troubleshooting.

The Particles Plus® architecture allows the swapping of subsystems to create different instruments with different feature sets without requiring extensive firmware or hardware changes to the system itself. For example, a user can replace a standard temperature/humidity sensor with a higher accuracy version of this sensor and the instrument will detect the change and adjust the displays accordingly to reflect the new sensor. Or, the temperature humidity sensor could be replaced with a completely different sensor type (air velocity, differential pressure, CO, CO2, etc.) and the instrument would detect the change and reconfigure itself to display the appropriate sensor data. The user can also swap batteries, substituting the standard sized battery for a larger capacity model and the instrument would detect the change and adjust the charging and management accordingly.

Patented

External Interfaces

Particles Plus® instruments contain a rich set of external interfaces. The instruments have wired Ethernet, device USB and host USB interfaces. Optionally, Wi-Fi, RS-232 and RS-485 interfaces can be added.

Particles Plus® External Interfaces allow the instrument to communicate simultaneously in a wide variety of applications:

- Local portable USB printer can print a variety of paper reports

- USB Memory stick can save or set up the instrument configuration

- USB Memory stick can be used to transfer recorded data

- Wired/wireless links to view the instrument on a web page (multiple concurrent user-sessions)

- Wired/wireless links to access the instrument remotely using Modbus

- Wired/wireless links to access the instrument using JSON

- Wired/wireless links to access the instrument using Internet-of-things protocols

- RS-232 interface to access the instrument using Modbus

- RS-485 interface to access the instrument using Modbus

Notes:

- Modbus interfaces can be used by remote monitoring software to access the instrument data and configure the instrument

- Modbus interfaces are a superset of existing industry instrument formats and can be made to emulate other instrument manufacture’s register maps for compatibility

- Remote interfaces can be password protected

- All of the above interfaces can be active simultaneously at full speed

Having all the above interfaces available (or easily upgraded) within an instrument, provides flexibility to integrate the instrument into multiple applications. All of the interfaces listed above can be active simultaneously, at full speed, while the instrument is in full operation.

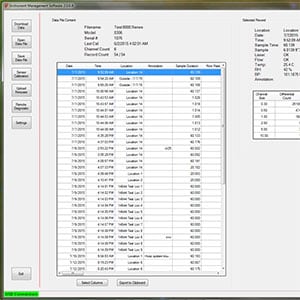

Instrument Management Software

Particles Plus® instruments include Instrument Management Software (IMS) on a USB memory stick, along with an electronic copy of the user manual and a quick-start guide. IMS allows users to retrieve stored data from the instrument, provides a means for the user to upgrade the instrument firmware (from files provided by Particles Plus) and allows the instrument to be serviced remotely.

It also provides the means for the user to calibrate for environmental sensors connected to the instrument. Sensors can be calibrated by selecting the environmental sensor in question and performing either a one-point (offset only) or two-point calibration for that sensor.

Partial or full data can be extracted with some or all of the fields for each record so the user can easily retrieve just the data they require for further analysis or archiving.