Optics Manufacturing

In Optics Manufacturing, where precision and clarity are of greatest importance, even the tiniest particle can cast a long shadow. Invisible to the naked eye, microscopic contaminants can disrupt delicate processes, mar pristine surfaces, and ultimately compromise the performance of sophisticated optical components. This is where particle counters emerge as the guardians of light, ensuring the quality and integrity of optical products through meticulous control over the manufacturing environment.

Imagine a single dust particle landing on the surface of a high-precision lens during assembly. This seemingly insignificant speck can scatter light, introducing unwanted aberrations and degrading the image quality. Particle counters, acting as eagle-eyed guardians, detect and measure such contaminants before they can cause irreversible damage.

By providing real-time data on particle levels, they enable manufacturers to implement targeted solutions to address contamination sources. This could involve upgrading air filtration systems, implementing stricter cleanroom protocols, or modifying manufacturing processes to minimize particle generation.

The benefits of utilizing particle counters in optics manufacturing are multifaceted:

Enhanced product quality

By preventing contamination, particle counters ensure the optical clarity and performance of lenses, mirrors, and other components. This translates to superior image quality, increased efficiency of optical systems, and ultimately, a higher level of customer satisfaction.

Reduced production costs

Minimizing contamination reduces the risk of product defects and rejections, leading to lower production costs. Particle counters help optimize manufacturing processes, eliminating unnecessary waste and maximizing yield.

Compliance with regulations

Many industries that rely on optical technologies, like aerospace and medical devices, adhere to strict regulations regarding particle contamination. Particle counters provide the data needed to ensure compliance with these regulations, mitigating risks and ensuring product safety.

As optics technologies continue to evolve, the need for even stricter particle control becomes increasingly important. Particle counters play an ever-expanding role in the manufacturing of next-generation optical products, ensuring their reliability and performance in the ever-evolving technological landscape.

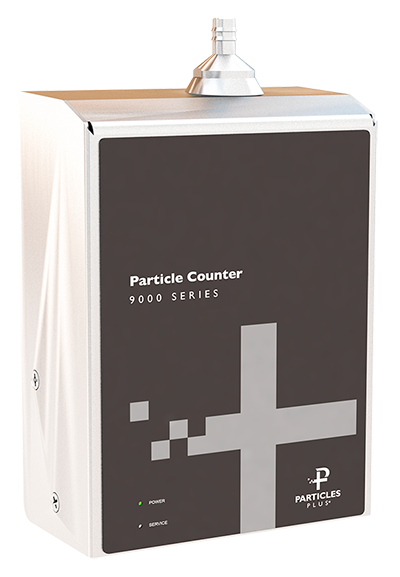

Particles Plus Instruments for Optics Manufacturing

Remote Air Quality Monitors

Particles Plus® instruments allow for remote operation and diagnostics over an IP connection from anywhere in the world. The remote diagnostics allows the Particles Plus® authorized technical staff to access the instrument and diagnose issues quickly, often without having to send the instrument in for service. This feature also allows for field-upgrades of the instrument software so updates and new capabilities can be added as they become available.