Pharmaceutical

Particle counting in the pharmaceutical industry plays a critical role in ensuring the safety, quality, and efficacy of pharmaceutical products. It involves the measurement and analysis of both viable and non-viable particles in controlled environments, such as cleanrooms and manufacturing facilities. Particle counters are indispensable tools used to monitor and maintain the desired levels of cleanliness and to identify potential contaminants that could compromise the integrity of a pharmaceutical product.

Quality Assurance and Regulatory Compliance

One of the primary reasons why particle counters are indispensable in the pharmaceutical industry is for quality assurance and to meet stringent regulatory standards that exist today. Particle counts provide crucial data that help pharmaceutical manufacturers and regulatory bodies ensure compliance with various international guidelines such as those issued by the United States Pharmacopeia (USP), the European Pharmacopoeia (EP), and the World Health Organization (WHO). These regulations specify acceptable limits for particle contamination in cleanrooms, manufacturing processes, and finished pharmaceutical products.

Preventing Contamination and Ensuring Product Safety

In pharmaceutical manufacturing, maintaining a controlled environment with low particulate levels is paramount in preventing contamination. Even microscopic particles can have detrimental effects on product safety and patient health. Particle counters enable continuous monitoring of the air, surfaces, and equipment within the manufacturing environment to identify potential sources of contamination so corrective actions can be taken promptly.

Optimizing Manufacturing Processes

Particle counters are also essential tools for optimizing manufacturing processes in the pharmaceutical industry. Continuous monitoring enables real-time data analysis, allowing manufacturers to identify trends, patterns, and anomalies in particle levels. By tracking these trends, companies can identify potential sources of contamination, design and implement suitable process improvements, and reduce production downtime.

Enhancing Product Quality and Efficacy

The presence of unwanted particles can directly impact the quality and efficacy of pharmaceutical products. Particle contamination can cause physical defects, alter drug stability, and potentially affect the pharmacological activity of the formulation. By utilizing particle counters, manufacturers can detect and quantify particles, enabling them to establish and maintain strict quality control measures. This ensures that pharmaceutical products consistently meet the required standards of quality, purity, and efficacy.

Particle counters play a vital role in maintaining the high standards of cleanliness, product safety, and regulatory compliance required in the pharmaceutical industry. Their ability to monitor and quantify particle contamination enables manufacturers to identify and mitigate potential sources of contamination, optimize manufacturing processes, and ensure the quality and efficacy of pharmaceutical products.

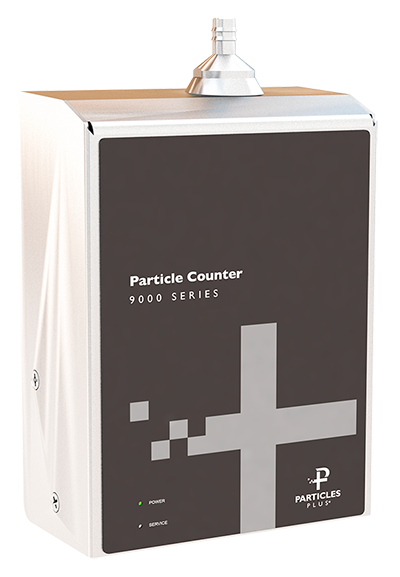

Particles Plus Instruments for Pharmaceutical

Remote Air Quality Monitors

Particles Plus® instruments allow for remote operation and diagnostics over an IP connection from anywhere in the world. The remote diagnostics allows the Particles Plus® authorized technical staff to access the instrument and diagnose issues quickly, often without having to send the instrument in for service. This feature also allows for field-upgrades of the instrument software so updates and new capabilities can be added as they become available.