Boston, MA – November 10, 2020 – Particles Plus, Inc., an engineering and manufacturing company located in Stoughton, Massachusetts, sought to apply computational fluid dynamics (CFD) and single-particle tracking simulations to analyses of the flow-field within a particle counter. The company selected AGS Consulting, LLC to partner with because of their reputation for product design and optimization. They selected NUMECA to perform the CFD analysis because of their reputation for simulation tools that accurately predict real-world product performance.

“Our objective in working with AGS and NUMECA was to predict particle motion within the particle counter itself, facilitating optimization of the particle counter geometry. Our experience is that better design minimizes recirculation of particles within the particle counter, irrespective of particle size,” said Adam Giandomenico, President, Particles Plus. Working collaboratively with AGS Consulting, LLC and NUMECA, Particles Plus, Inc. commenced development of their next generation of particle counters.

The numerical process adopted comprised two steps. First, modeling the particle counter flow-field that constitutes the particles’ support media. Second, calculating the trajectory of particles as they pass through the particle counter.

Due to the complexity of the geometry, engineers at NUMECA chose to work with FINE™/Open w/OpenLabs, using the unstructured meshing capabilities of Hexpress™. First, for comparison with experimental results, flow-field simulations were run in FINE™/Open to predict pressure-drop through the particle counter. Here a pressure-based solver was used, which is faster and more accurate for incompressible flow-field simulations.

Single particle tracking was used to predict the trajectory of different sized particles through the particle counter. Particles were launched from the inlet, and trajectories calculated as they passed through the particle counter chamber. Two assumptions were made when calculating trajectory:

- Particle trajectory is driven by the flow-field within the particle counter. However, particles’ do not have a significant impact on the flow-field. The particle-to-air ratio is considered low enough that this one-way coupling approach may be assumed valid.

- Particle-to-particle interaction is neglected. Again, the particle-to-air ratio is considered low enough that this approach may be assumed valid.

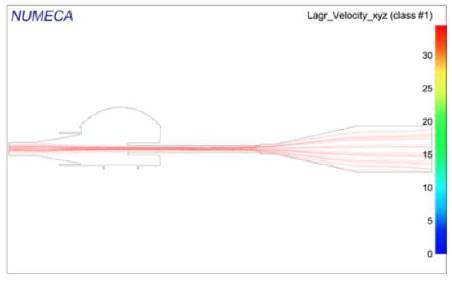

The results were enlightening. The horizontal and vertical cutting planes through the particle counter were defined and particle trajectories mapped onto each plane. The trajectories of Class 1, 2 and 3 particles were studied over the vertical plane, with each class of particle behaving differently:

- The Class 1 (5.0 micrometer) particles pass through the chamber.

- The Class 3 (0.3 micrometer) particles recirculated in the vicinity of the chamber exit. However, they do not migrate back into the main body of the chamber.

- The Class 2 (1.0 micrometer) particles both recirculated in the vicinity of the chamber exit and, critically, do migrate back into the main body of the chamber.

When particle trajectory was studied over the horizontal cutting plane, particle trajectories were concluded to be similar, with the exception of Class 2 particles. The Class 2 particles exhibited a more intense recirculation at the exit of the chamber. The intensity of this recirculation was tentatively concluded to be driving migration of Class 2 particles back into the main body of the chamber.

When particle trajectory was studied over the horizontal cutting plane, particle trajectories were concluded to be similar, with the exception of Class 2 particles. The Class 2 particles exhibited a more intense recirculation at the exit of the chamber. The intensity of this recirculation was tentatively concluded to be driving migration of Class 2 particles back into the main body of the chamber.

Overall, AGS Consulting, LLC and NUMECA collaborated with Particles Plus, Inc. to develop an experimentally validated CFD simulation of the flow-field within a particle counter. This simulation was used to identify that large, medium and small particles behave differently as they pass through the particle counter. The two-step transfer of 1.0 micrometer particles from inlet-jet to exit-recirculation and then exit-recirculation to main-chamber recirculation was not anticipated. This insight into particle counter flow-field physics, and the associated physical mechanisms at play within the particle counter, have provided Particles Plus with the basis for an on-going project aimed at identifying critical particle sizes prone to recirculation, and the optimization of particle counter geometry to minimize that recirculation.

For technical questions, product information or pricing, contact Particles Plus today.

(Portions of this article are reprinted with permission from Geoff Sheard, President of AGS Consulting, LLC.)